as per the policy of company to assure the highest level of quality to our customers, our Quality Assurance Department has developed a Quality Management System (QMS) which makes sure that regular quality tests are performed at each level of value addition. Our QMS is designed in such a way that if any flaw is found in any batch of production, it is instantly logged out of the process and disposes off so as to avoid any complaints from our prestigious customers. From raw scrap to production of billets and then till final dispatch of Deformed Steel Bars we make sure that all quality measures are taken and the products manufactured are strictly as per the specifications of their respective ASTM Standards.

Our laboratory consists of following testing equipments:

|

|

Grade 40 Grade 60 |

|

|

Tensile strength, min psi |

70,000 |

90,000 |

|

Yield strength, min, psi |

40,000 |

60,000 |

|

Elongation in 8 in, min, % |

||

|

Bar No |

||

|

3 |

11 |

9 |

| 4,5,6, |

12 |

9 |

| 7,8 |

... |

8 |

| 9,10 |

... |

7 |

| 11,14,18 | 7 | |

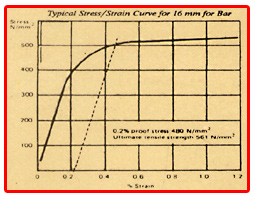

| S.No | Wt.Rft.Lbs | Dia in | Area in2 | Yield Load Tons | Ultimate Load Tons | Yield Stress Psi | Ultimate Strees Psi | Elong-ation in | Percentage Elonagation | Remarks |

| 1 | 2.672 | 1.000 | 0.785 | 23.00 | 32.60 | 65650 | 93000 | 1.30 | 16.25 | |

| 2 | 2.060 | 0.878 | 0.605 | 17.00 | 26.50 | 62950 | 98100 | 1.30 | 16.25 | |

| 3 | 1.507 | 0.751 | 0.443 | 13.00 | 21.60 | 65750 | 109200 | 1.20 | 15.00 | |

| 4 | 1.046 | 0.625 | 0.307 | 10.00 | 13.70 | 72950 | 99950 | 1.20 | 15.00 | |

| 5 | 0.668 | 0.500 | 0.196 | 6.20 | 8.20 | 70850 | 93700 | 1.30 | 16.25 | |

| 6 | 0.398 | 0.386 | 0.117 | 3.60 | 5.30 | 68900 | 101450 | 1.20 | 15.00 |

|

SIZE m m. |

Area sq.cm. |

Wt kg/metre |

Length metres/tonne |

Size inch |

Area sq.in |

Wt. Ib/ft |

Length ft/cwt. |

Recom-mended Bend Radius |

|

6 |

0.283 |

0.222 |

4500 |

¼ |

0.0491 |

0.167 |

672 |

|

|

8 |

0.503 |

0.394 |

2532 |

|

|

|

|

|

|

10 |

0.785 |

0.617 |

1621 |

3/8 |

0.1105 |

0.376 |

298 |

|

|

12 |

1.131 |

0.888 |

1125 |

½ |

0.1964 |

0.668 |

168 |

|

|

14 |

1.539 |

1.208 |

829 |

5/8 |

0.3068 |

1.04 |

108 |

|

|

16 |

2.011 |

1.578 |

633 |

¾ |

0.4418 |

1.50 |

74.5 |

4d* |

|

18 |

2.545 |

2.000 |

500 |

7/8 |

0.6013 |

2.04 |

55 |

|

|

20 |

3.142 |

2.466 |

405 |

1 |

0.7854 |

2.67 |

42 |

|

|

22 |

3.801 |

2.980 |

336 |

|

|

|

|

|

|

25 |

4.909 |

3.854 |

260 |

|

|

|

|

|

|

28 |

6.157 |

4.830 |

207 |

1.1/8 |

0.9940 |

3.38 |

33 |

6d* |

|

32 |

8.042 |

6.313 |

159 |

1 ¼ |

1.227 |

4.17 |

27 |

… |